DPMO

DPMO - Defects Per Million Opportunities

DPMO means Defects Per Million Opportunities. It is an easy method of measuring process performance often used in Six Sigma initiatives.

Unlike Defects Per Unit (DPU), which provides the number of defects in a product, DPMO takes into account the reality that multiple defects can exist in a single product. It also serves as a basis for calculating process sigma values, another six sigma performance measure.

How to Calculate DPMO

First, you'll need to figure out the number of opportunities for

defects that exist in one unit. To do this, count everything that could be

wrong with the product that is also important to your customers.

Let's say you produce electronic equipment, and each equipment is made up of 10

parts. Each one of those parts could be an opportunity for a defect if a

problem would be undesirable to a customer.

Now, let's say your customer wants the equipment delivered within

5 business days. Since delivery time is important to your customer, late

delivery is also a defect. If your customer doesn't care about the color, then

a difference in color is not a defect.

Once you've listed all the possible defects opportunities in your product or

service, count them up and now you know the number of opportunities per unit.

Next, you need to sample some data to determine the total number of defects the process is producing. The more samples you have, the more reliable your measure will be. For each unit examined, count the number of defects you find. Count how many samples you inspected (number of units) and the number of defects you found.

Now that you have the data, you are one simple calculation away from

finding your DPMO: (Number of Defects x 1,000,0000)

/ (Number of Units x Number of opportunities).

Electronic Equipment

Defects Calculation:

Number of Defects: 9

Number of Opportunities per unit: 11 (10 parts + shipping time)

Number of Units: 30 (electronic equipments that were inspected)

DPMO = (9 x 1,000,000)/(11x30)=27,273

In plain English, if your factory produced one million same electronic

equipments, we could expect to end up with 27273 defects in those electronic equipment.

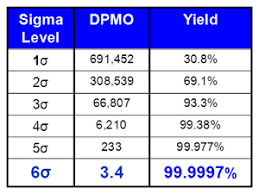

This figure can now also be checked in the Six Sigma chart or Z score level which tells us at what level of sigma the process output is.

3 sigma is 66807 defects; 4 sigma is 6210 defects. So 27273 defects is definitely between 3 and 4. Or roughly speaking 3.5

This process performance may have a room for more improvement by reducing the defects and moving the sigma level to 6 which is just 3.4 defects per million opportunities.

DPMO is very important metric in Six Sigma domain. This is rather one of the simplistic metrics which can directly be measured by taking the process outputs/yield. All the defects (which are not conforming to the customer requirements) can be measured and the consequent sigma level can be determined.

It is also one of the diagnostic strategies which any six sigma consultant may adopt first, before planning further any six sigma project. As it says, ‘don’t fix it if it ain’t broke’.